Key Factors That Influence Washing Machine Belt Durability

Lifespan and Typical Usage Conditions of Washing Machine Belts

Modern washing machine belts typically last 5–8 years under standard conditions, handling 3–5 weekly cycles. Their lifespan depends on three critical variables:

- Cycle regularity: Frequent use (7+ weekly loads) accelerates wear by 30% compared to moderate usage

- Environmental exposure: Humidity levels above 60% promote rubber degradation

- Mechanical alignment: Proper pulley positioning reduces lateral friction forces

Impact of Overloading, Frequency of Use, and Mechanical Stress

Overloading your washer by just 20% (≈3.5 kg beyond capacity) increases belt tension forces by 37%, according to appliance engineering principles. This creates three failure pathways:

- Fiber separation in multi-ply belts from torque overload

- Groove deformation in V-shaped belts

- Thermal fatigue from prolonged motor slippage

High-frequency households (10+ weekly cycles) should prioritize belts with reinforced nylon cores, which demonstrate 82% lower fracture rates in accelerated testing.

Role of Temperature, Humidity, and Operational Pressure on Belt Wear

Operational heat from motor friction can elevate belt temperatures to 71°C (160°F), exceeding standard rubber’s optimal range of 10–50°C. This thermal stress causes:

| Condition | Effect on Belt Material | Failure Timeline |

|---|---|---|

| 65%+ humidity | Hydrolysis of polymer chains | 3–4 years |

| <30% humidity | Cracking from dryness | 5–6 years |

| Heavy loads | Ply separation under 12–15 bar pressure | 2–3 years |

Proper ventilation reduces operational humidity by 40%, while pressure-regulated models maintain optimal 8–10 bar tension during spin cycles.

High-Quality Materials and Engineering Behind Long-Lasting Washing Machine Belts

Common Materials Used in Durable Washing Machine Belts

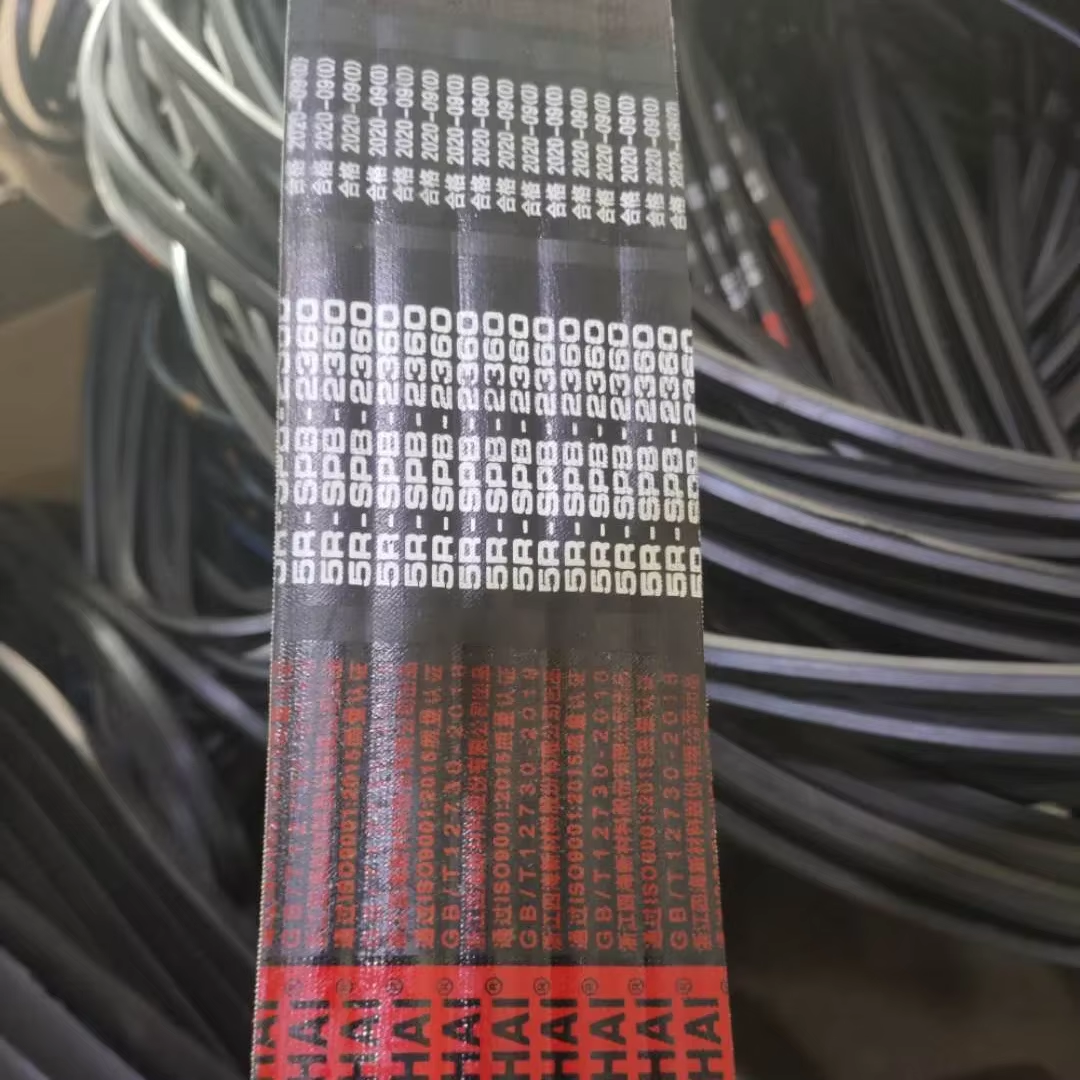

The belts in modern washing machines need to be both flexible enough to bend around pulleys but also tough enough to last through years of use. That's why most manufacturers turn to polyurethane (PU) material these days. PU stands up pretty well against things that would normally wear out regular rubber belts, including abrasion from dirt and grime, exposure to oils inside the machine, and even temperature changes all the way up to around 200 degrees Fahrenheit. When making belts for really tough jobs, companies often add steel cores or special synthetic fibers like aramid to keep them from stretching out over time when they're carrying weight. Some newer models also use advanced rubber mixtures with heat resistant additives built right in. These special treatments help stop the belt from breaking down when exposed to moisture or constant mechanical stress during operation. All these different materials come together so the belt stays grippy on those spinning parts and doesn't develop tiny cracks from all the normal vibrations that happen every time someone does laundry.

Material Innovations That Enhance Resilience and Flexibility

The latest improvements involve composite structures made from several different materials stacked together to boost overall performance. Manufacturers have started incorporating thermoplastic elastomers mixed with woven fabric layers which spread out the pressure better and cuts down on those annoying hotspots where wear happens fastest. A few newer models come with special silicone coatings applied to their surfaces. These coatings cut back on the friction when the belt rubs against motor pulleys, so they tend to last about 40 percent longer than older versions did. Another neat trick is adding microscopic grooves to surface areas. This helps keep dirt and grime from collecting there, something that usually leads to early failure. At the same time, these grooves maintain good power transmission even when machines experience uneven spinning conditions.

Industry Testing Standards and Accelerated Life Tests for Belt Reliability

Most top manufacturers put their products through the wringer with ASTM F2703-15 accelerated life testing. This basically means they simulate what would happen after a decade of regular use but condense it into just 500 hours. The test subjects are spun at crazy speeds (think around 1,800 RPM) while being subjected to wild temperature swings from freezing cold at -40°F all the way up to blistering heat of 250°F. Then there's also ISO 4183:2019 to contend with, which demands that belts survive over 100,000 stress cycles without showing any signs of cracking or stretching past 2%. That kind of spec ensures belts perform reliably even when faced with unpredictable loading conditions. What makes these tests so valuable is that they force engineers to tweak material recipes to handle actual problems encountered in the field such as sudden changes in humidity levels or contact with harsh cleaning chemicals during maintenance routines.

Signs of Wear and Performance Impact of a Failing Washing Machine Belt

How Belt Condition Affects Washing Machine Efficiency and Noise

When belts start wearing out they tend to lose their tension which messes up how power gets transferred from the motor to the drum. What happens next? Wash cycles take longer - sometimes around 15% extra time - while using between 10 and 20% more electricity according to figures released last year by Appliance Standards Group. Listen closely too because noise is actually one of the first signs something's wrong. Grinding noises, high pitched squeals, or that repetitive slap sound usually mean the belt is slipping or wearing unevenly somewhere. Most appliance repair folks will tell customers that about three quarters of all early belt failures come with some kind of warning sound beforehand as per stats from National Appliance Repair Association.

Early Warning Signs of Belt Degradation or Misalignment

Proactive monitoring helps avoid sudden breakdowns. Key indicators include:

- Uneven wear patterns: Frayed edges or cracks suggest pulley misalignment

- Glazing: Shiny sections indicate excessive friction from slippage

- Vibration: Irregular drum movement during spins often stems from belt instability

The Environmental Protection Agency’s 2024 appliance maintenance report notes that 68% of washing machine failures begin with undetected belt issues.

Common Symptoms Indicating the Need for Belt Replacement

Persistent problems confirm imminent failure:

- The drum stops rotating mid-cycle despite motor operation

- A burnt rubber odor indicates overheating

- Visible elongation exceeding 3% of the original length

Manufacturers like Whirlpool and LG design belts for 8–10 years of average use, but 2023 field data shows 34% require replacement within 5 years due to improper loading habits. Addressing these signs promptly restores efficiency and prevents damage to bearings and pulleys.

Maintenance Practices to Extend Washing Machine Belt Life

Routine inspection and cleaning of the washing machine belt

Perform monthly visual checks for cracks, fraying, or glazing. Clean pulley grooves and belt surfaces with a dry cloth to remove detergent residue and lint—contaminants that increase wear by 28% in reliability studies. Test tension by pressing the midpoint; optimal deflection is ½" (12mm) under moderate finger pressure.

Best practices for operating your washer to minimize belt strain

- Limit loads to 85% drum capacity to reduce torque spikes

- Use warm water (90–110°F / 32–43°C) instead of hot to prevent rubber hardening

- Avoid single-item cycles, which create unbalanced centrifugal forces

- Allow 15-minute cool-down intervals between consecutive washes

Proactive maintenance tips to maximize appliance lifespan

Replace belts preventatively every 6–8 years, following manufacturer recommendations. Store spare belts in breathable containers at 40–60% humidity to prevent premature aging. Annual professional alignment checks resolve 93% of early wear cases linked to misaligned pulleys.

Long-Term Cost Savings and Sustainability of Durable Washing Machine Belts

Reduced Replacement Frequency and Repair Costs Over Time

Belts crafted from advanced polymer materials tend to outlast regular ones by around two to four times. Standard belts usually give out somewhere between 12 and 18 months. According to a recent look at maintenance expenses in 2024, families can actually pocket anywhere from $90 to almost $180 each year just by not having to replace them two or three times. Think about it this way: when someone invests in a quality belt that lasts about eight years, they cut down on replacements by half and knock around 35% off those pesky repair bills. And there's another benefit nobody talks about enough. Durable belts stop these chain reactions of problems. We've seen data showing worn out belts are responsible for nearly 40% of all drum bearing replacements, which happens to be one of the pricier fixes for washing machine owners.

Environmental and Economic Benefits of Durable Components

Belts that last longer mean fewer appliances end up in landfills when they break down. When we avoid replacing these parts, we're actually keeping around 2.4 kilograms of rubber and plastic materials out of waste streams each time. That's roughly what happens if someone recycles about 110 plastic bottles worth of material. Getting the tension right on those belts makes motors work better too. Studies show efficiency gains between 12% and 18%, which adds up to saving roughly 30 kilowatt hours every year for most households. Think about it over the course of a washing machine's typical 10 years in service, and suddenly we're talking about preventing 45 kilograms of carbon dioxide from entering the atmosphere. To put that into perspective, it's kind of like having seven fully grown oak trees absorbing all that CO2 naturally. The good news is many appliance makers now design their products with sustainability in mind. Companies like Whirlpool and Samsung have started incorporating modular belt systems that let technicians fix just the broken part rather than tossing the whole unit into the trash bin.

Frequently Asked Questions

How often should I replace my washing machine belt?

It is recommended to replace washing machine belts preventatively every 6-8 years and follow manufacturer guidelines for best results.

What are signs that my washing machine belt needs replacement?

Common signs include a burnt rubber odor, visible elongation exceeding 3% of the original length, and the drum stopping mid-cycle.

Can overloading the washer damage the belt?

Yes, overloading beyond capacity increases tension forces, leading to potential wear and failure pathways like fiber separation and groove deformation.

How can I maintain my washing machine belt to extend its life?

Perform regular inspections, avoid overloading, clean pulley grooves, use warm water, and allow cooling periods between washes to extend belt lifespan.

Table of Contents

- Key Factors That Influence Washing Machine Belt Durability

- High-Quality Materials and Engineering Behind Long-Lasting Washing Machine Belts

- Signs of Wear and Performance Impact of a Failing Washing Machine Belt

- Maintenance Practices to Extend Washing Machine Belt Life

- Long-Term Cost Savings and Sustainability of Durable Washing Machine Belts

- Frequently Asked Questions