Understanding Conveyor Belt Use in Coal Mining and High-Temperature Environments

The conveyor systems used in coal mines face serious heat challenges, especially around the processing areas and down those deep shafts where temps can hit over 300 degrees Fahrenheit, which is about 150 Celsius. Regular rubber belts just aren't cut out for this kind of punishment. They tend to get all gooey and start cracking after sitting in that heat too long, and nobody wants a belt failure right in the middle of maximum production time. That's why miners have started using these special heat resistant belts instead. These upgraded versions stay pliable even while moving fresh coal that's still hot from being extracted. Traditional materials would literally bend out of shape under those conditions, but not these newer alternatives.

Challenges of Transporting Hot Materials with Standard Conveyor Belts

In 2022, the American mining sector brought in around $900 billion worth of economic activity, and just look at Appalachia where they move well over 200 million tons of coal every year according to the North America Conveyor Belt Market Report. The problem comes when mines use belts that can't handle heat. These standard belts end up needing about 40% more unexpected shutdown time because they break down from getting too hot. What happens? The rubber layers start peeling apart, and the hot materials wearing them down much faster than normal. When this occurs, it messes up the whole ventilation system which is already tricky enough underground. And there's something else really dangerous happening too – increased risk of fires in areas full of methane gas makes everyone worry about safety day and night.

Why Heat-Resistant Conveyor Belts Are Essential for Underground Coal Mine Safety and Efficiency

Today's heat resistant conveyor belts can handle temps as high as 400 degrees Fahrenheit (that's around 204 Celsius) without losing their structural integrity. These belts cut down on fire risks by almost 60% when compared to older versions according to recent market research studies. What makes them so tough? They're made from special composites reinforced with those strong aramid fibers we see in bulletproof vests, plus fabrics coated with ceramics that resist heat damage. In industrial settings where temperatures run hot, these upgraded belts last anywhere from three to five extra years before needing replacement. For mining operations specifically, this means massive long term savings. A single mile of these belts saves approximately $2.3 million over ten years worth of operation. Plus they meet all the stringent flame resistance requirements set by MSHA for equipment used deep underground where safety is absolutely critical.

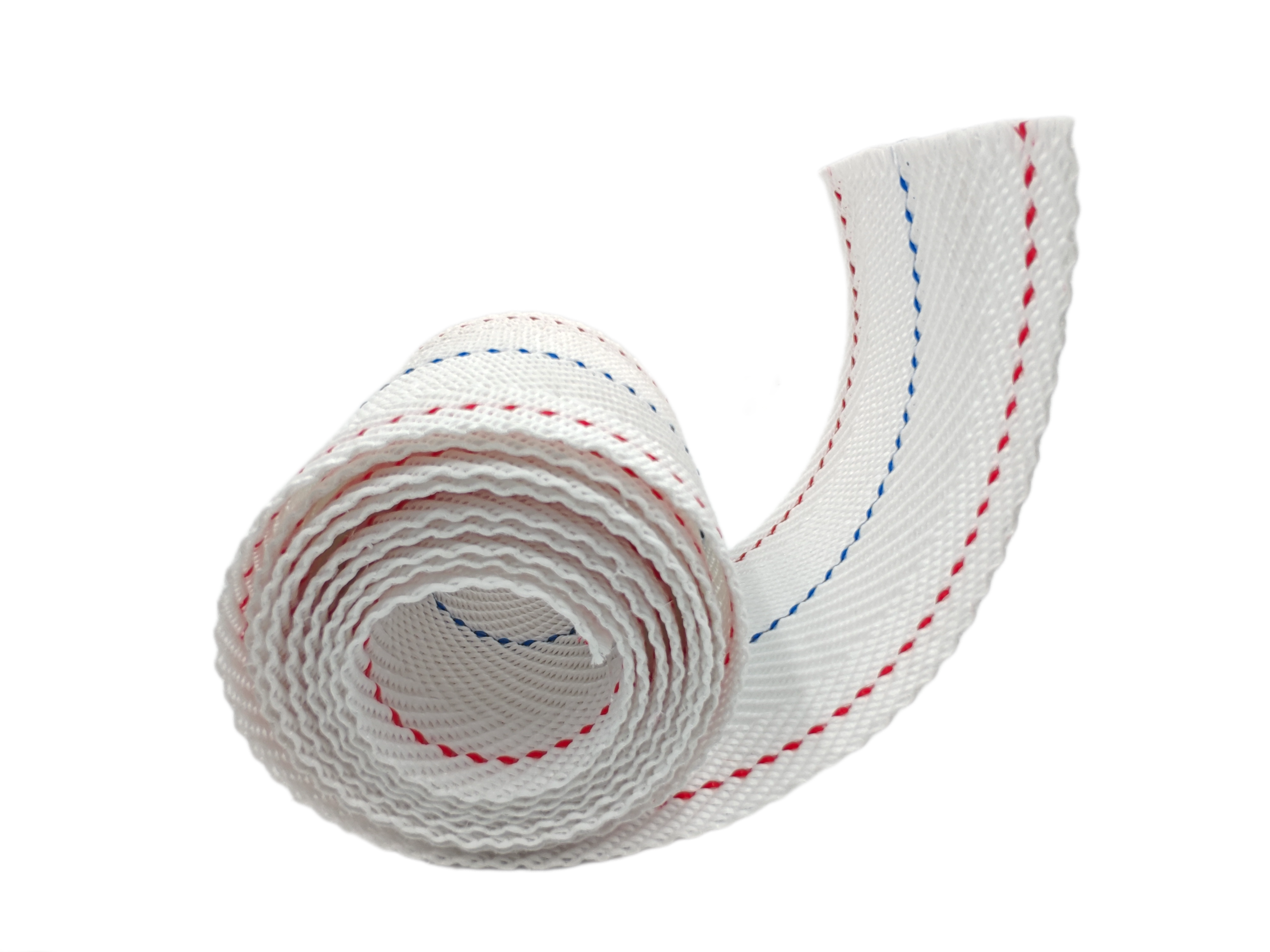

Material Science and Composition of Heat-Resistant Conveyor Belts

Rubber compounds and reinforcing layers in heat-resistant mining conveyor belts

Conveyor belts designed to withstand heat typically mix special rubber blends with multiple layers of reinforcement so they can survive tough operating environments. Most manufacturers formulate their base rubber with things like silicone and graphite additives, which helps keep the material flexible even when temperatures climb past 150 degrees Celsius. This is really important in mining operations where fresh coal comes out of the ground still hot from blasting and drilling. To make these belts last longer, companies reinforce them with strong materials like steel cords or fabric hybrids. These reinforcements not only give the belt extra strength but also let it expand and contract without breaking down under thermal stress during operation.

Thermal stability and abrasion resistance: How conveyor belts withstand extreme heat

Multilayer construction enables simultaneous heat dissipation and surface protection:

| Layer Type | Function | Temperature Threshold |

|---|---|---|

| Top Cover | Resist abrasion from sharp coal edges | Up to 200°C |

| Intermediate Cushion | Absorb impact forces | 180°C sustained |

| Core Reinforcement | Maintain tensile strength during expansion | 220°C peak resistance |

This stratified design allows surface layers to shield inner components while channeling heat away from vulnerable areas, reducing delamination risks.

Advancements in material technology for improved environmental adaptability

New developments are tackling two big problems facing coal miners every day: excessive heat and dangerous particulate exposure. The latest innovation comes in the form of rubber coatings embedded with ceramics, which last around 43 percent longer than what we've been using before in those really rough areas where wear and tear happens fast. Meanwhile, top companies in the sector are starting to roll out these self cleaning polymer surfaces across their operations. These surfaces stop flammable coal dust from building up on equipment, something that matters a lot since almost one out of seven underground accidents actually starts with fires related to conveyor belts according to data from Mining Safety Institute back in 2023. This kind of tech isn't just about compliance anymore it's becoming essential for keeping workers safe while also cutting down on maintenance costs over time.

Balancing heat resistance with mechanical strength: Key trade-offs in design

Engineers working with materials have been wrestling with a tricky problem for years - when they boost a belt's ability to withstand heat, it usually comes at the cost of making the belt less flexible. The good news is that new simulation tools are changing things. Designers can now get belts that bend almost as well as regular ones (about 92% of their bend radius) without sacrificing their heat resistance up to 180 degrees Celsius. This makes all the difference for installations in mining operations where space is really tight between those vertical transfer points. Getting this right has solved a major headache from older heat resistant belts that would crack when starting up cold, something that caused plenty of downtime and frustration on site.

Engineering and Safety Design of Fire-Resistant Conveyor Belt Systems

Design Principles for Fire-Resistant Conveyor Belts in Underground Mining

When it comes to fire resistant conveyor belts, there are really three main things manufacturers focus on first: stopping flames from spreading, keeping the belt strong even when exposed to high temperatures, and controlling toxic smoke emissions. According to a recent study published by ISO in 2023, conveyor belts that meet the ISO 340 standard actually cut down fire spread risks by around two thirds compared with regular belts. The latest belt designs incorporate multiple layers made with special rubber compounds reinforced with ceramics, which helps form protective thermal barriers without sacrificing the belt's ability to bend and move. What makes these belts truly effective? They contain materials that put themselves out once ignited, plus their surfaces resist friction enough to stop sparks from forming where the belt meets rollers during operation.

Layered Construction and Flame-Retardant Additives in Modern Conveyor Belts

Advanced conveyor belts combine 4–7 functional layers for optimal fire resistance:

- Top cover rubber with aluminum trihydrate additives to absorb heat (up to 300°C continuous exposure)

- Flame-retardant fabric plies treated with chloroprene coatings

- Aramid-reinforced carcass layers maintaining tensile strength during thermal expansion

- Bottom abrasion-resistant layer with antistatic compounds

Recent material advancements have improved heat dissipation rates by 40% compared to 2018 designs, as demonstrated in controlled mine simulations.

Compliance With International Safety Standards for Mining Conveyor Belts

Global certification requirements mandate rigorous testing:

- EN 14973 flame resistance certification (withstands 800°C flame for 15+ minutes)

- MSHA-approved drum friction tests simulating emergency braking scenarios

- RATPEN directive smoke density compliance (<10% opacity after 5-minute fire exposure)

A 2022 analysis of 17 international coal mines showed facilities using fully certified belts experienced 89% fewer fire-related downtime incidents than those using non-compliant alternatives.

Performance and Long-Term Benefits in High-Temperature Mining Environments

Evaluating Real-World Performance of Conveyor Belts Under Continuous High Heat

Conveyor belts designed to withstand heat keep their shape even after sitting in temperatures over 150 degrees Celsius for hours on end. Tests run at lignite mining sites show these special belts cut down on material warping problems by around 83 percent compared with regular belts. This means operations can keep running non-stop without slowing down the movement of coal through the system according to the latest Mining Materials Report from 2023. What makes them work so well? The belts have multiple layers built right in, which stops too much heat from getting through to what's inside. That layering helps stop the belts from coming apart at the seams when things get hot.

Case Study: Failure Analysis of Non-Heat-Resistant Belts in a Deep Coal Mine

A 1,200-meter-deep Indonesian mine experienced 14 unplanned stoppages monthly with conventional belts, costing $290k in lost productivity annually. Post-failure inspections revealed:

- Cracked inner layers from thermal cycling

- Accelerated wear at splice joints (3.2mm/month vs. 0.8mm in heat-resistant models)

- Ignition risks from friction-induced hot spots

Extending Service Life and Reducing Downtime With Heat-Resistant Conveyor Belts

Heat resistant belts that get regular care last between 18 to 24 months in environments where temperatures run really high, which is about three times what generic belts manage before needing replacement. The reason these specialized belts hold up so well? They're made with rubber that resists oxidation, reinforced with aramid fibers for strength, and feature ceramic components in areas that take the most beating. When manufacturers implement smart maintenance routines such as checking belt temperature with infrared scanners and keeping proper tension levels, they can cut down on replacements by around 40 percent over time compared to waiting until something breaks before fixing it. This makes sense both economically and operationally for facilities dealing with intense heat conditions day after day.

Cost Analysis: Higher Initial Investment vs. Long-Term Operational Savings

While heat-resistant conveyor belts command a 60–80% upfront cost premium, they deliver a 7-year ROI of 210% in high-heat mines. A 2023 lifecycle analysis found:

| Cost Factor | Standard Belt | Heat-Resistant Belt |

|---|---|---|

| Annual replacement costs | $48k | $16k |

| Downtime losses | $310k | $85k |

| Safety incident expenses | $72k | $9k |

Operators using heat-resistant models report 34% lower total cost per ton over 5-year periods, according to thermal management studies.

Installation and Maintenance Best Practices for Durability and Safety

Best Practices for Installing Conveyor Belts in Challenging Underground Conditions

Getting the installation right starts with making sure those conveyor frames line up pretty closely, ideally within about 3mm or so to avoid all sorts of tracking problems down the road. Most folks in the mining business recommend using laser guides for this part since they just make things so much easier. When it comes to tensioning belts, thermal expansion is something that really matters. Industry pros generally tell us to set the initial tension around 1.5% of the belt's total length for each 10 degree Celsius change in temperature. And don't forget about fire resistance either. The lagging material needs to wrap around roughly 85 to 90 percent of those drive pulleys. This gives enough grip to keep everything moving smoothly but still lets loose material fall off instead of building up and causing trouble later on.

Routine Maintenance Strategies to Maximize Conveyor Belt Lifespan Under Heat and Abrasion

A 2023 bulk material handling study revealed systems with automated thermal imaging catch 43% more early-stage belt degradation than visual inspections alone. Critical maintenance tasks include:

- Weekly: Clean return rollers with compressed air (<100 psi) to remove combustible coal dust

- Monthly: Measure pulley alignment using digital inclinometers (<0.5° deviation permitted)

- Quarterly: Replace sacrificial heat-resistant skirting when wear exceeds 8mm thickness

Operators implementing ultrasonic splice monitoring every 500 operational hours report 31% fewer catastrophic belt failures compared to conventional maintenance schedules. Proper storage of spare belts in climate-controlled areas (15–25°C, 40% humidity) preserves rubber compound integrity between replacements.

Frequently Asked Questions

What makes heat-resistant conveyor belts different from standard belts?

Heat-resistant conveyor belts are designed with special materials and reinforcements, such as aramid fibers and ceramic coatings, to withstand high temperatures and reduce the risk of breakdowns and fires.

How do heat-resistant belts improve safety in coal mines?

These belts reduce fire risks by almost 60% and meet MSHA's stringent flame resistance requirements, making them essential for safe operations in high-temperature environments.

What are the cost benefits of investing in heat-resistant belts?

While the initial cost is higher, these belts save money in the long run by reducing downtime, cutting maintenance costs, and providing a 210% ROI over seven years.

How long do heat-resistant belts typically last?

When properly maintained, heat-resistant conveyor belts can last between 18 to 24 months in high-temperature environments.

Table of Contents

- Understanding Conveyor Belt Use in Coal Mining and High-Temperature Environments

- Challenges of Transporting Hot Materials with Standard Conveyor Belts

- Why Heat-Resistant Conveyor Belts Are Essential for Underground Coal Mine Safety and Efficiency

-

Material Science and Composition of Heat-Resistant Conveyor Belts

- Rubber compounds and reinforcing layers in heat-resistant mining conveyor belts

- Thermal stability and abrasion resistance: How conveyor belts withstand extreme heat

- Advancements in material technology for improved environmental adaptability

- Balancing heat resistance with mechanical strength: Key trade-offs in design

- Engineering and Safety Design of Fire-Resistant Conveyor Belt Systems

-

Performance and Long-Term Benefits in High-Temperature Mining Environments

- Evaluating Real-World Performance of Conveyor Belts Under Continuous High Heat

- Case Study: Failure Analysis of Non-Heat-Resistant Belts in a Deep Coal Mine

- Extending Service Life and Reducing Downtime With Heat-Resistant Conveyor Belts

- Cost Analysis: Higher Initial Investment vs. Long-Term Operational Savings

- Installation and Maintenance Best Practices for Durability and Safety

- Frequently Asked Questions