Πώς οι ζώνες μετάδοσης επιτρέπουν αποτελεσματική μετάδοση ισχύος στα συστήματα μειωτήρα κινητήρα

Τι είναι μια ζώνη μετάδοσης και πώς λειτουργεί στη μετάδοση ισχύος

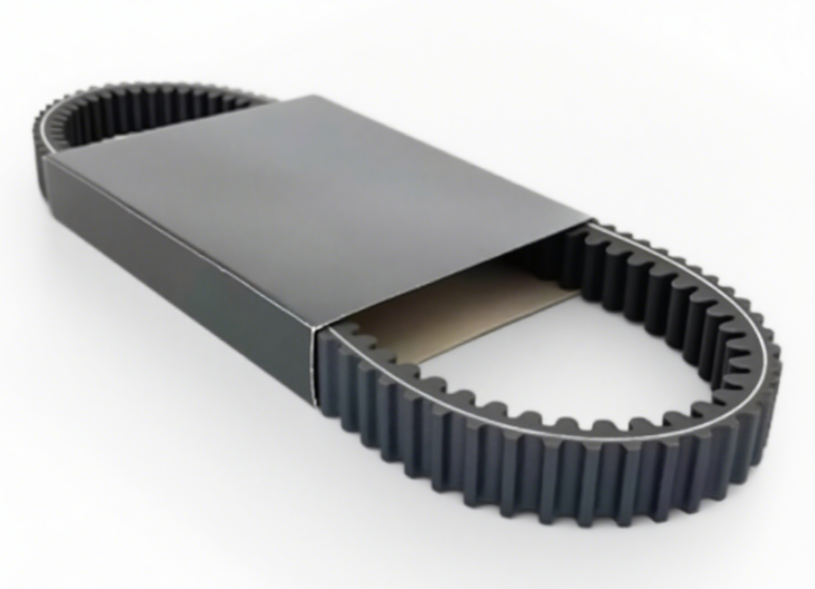

Οι ιμάντες μετάδοσης είναι στην ουσία μακριές δακτυλιοειδείς δομές κατασκευασμένες από ανθεκτικό καουτσούκ ή συνθετικά υλικά, οι οποίες βοηθούν στη μεταφορά της περιστροφικής κίνησης μεταξύ διαφόρων εξαρτημάτων μηχανημάτων. Όταν χρησιμοποιούνται σε συνδυασμό με μειωτήρες, οι ιμάντες αυτοί κινούνται πάνω σε τροχαλίες που είναι συνδεδεμένες τόσο στην πλευρά του κινητήρα (η είσοδος) όσο και στην πλευρά του μειωτήρα (η έξοδος). Λειτουργούν μέσω της τριβής για να μεταφέρουν τη ροπή, χωρίς να χρειάζεται να έρχονται σε επαφή μεταξύ τους τα μεταλλικά εξαρτήματα. Η κατασκευή τους συμβάλλει στη μείωση των δονήσεων και επιτρέπει μικρές ανοχές στη στοίχιση μεταξύ των εξαρτημάτων. Σύμφωνα με πρόσφατες εκθέσεις της βιομηχανίας, οι περισσότεροι σύγχρονοι ιμάντες μετάδοσης μπορούν να μεταφέρουν αποτελεσματικά περίπου το 92% της ισχύος. Αυτό που τους ξεχωρίζει σε σχέση με τις άκαμπτες μεταλλικές συζευγενώσεις είναι η δυνατότητά τους να απορροφούν κραδασμούς. Αυτό σημαίνει ότι προκαλείται λιγότερη φθορά σε σημαντικά εξαρτήματα, όπως οι τροχαλίες και οι οδοντωτοί τροχοί, όταν τα μηχανήματα ξεκινούν ή σταματούν απότομα.

Η Κρίσιμη Σημασία των Ιμάντων Μετάδοσης στη Σύνδεση Κινητήρων με Μειωτήρες

Σε βιομηχανικό και αγροτικό εξοπλισμό, οι διωστήριοι ιμάντες συνδέουν τους κινητήρες με τους μειωτήρες, επιτρέποντας τις σημαντικές μειώσεις ταχύτητας που είναι απαραίτητες όταν η ροπή είναι κρίσιμη. Η ελαστική φύση αυτών των ιμάντων βοηθάει στην πραγματικότητα στην αντιμετώπιση της διαστολής και συστολής των τροχαλιών καθώς μεταβάλλεται η θερμοκρασία, ενώ εμποδίζει την ολίσθηση όταν τα φορτία γίνονται πολύ βαριά. Μια πρόσφατη μελέτη το 2023 για τη θερμική απόδοση έδειξε κάτι ενδιαφέρον και σχετικά με αυτό. Όταν οι ιμάντες διατηρούνται στη σωστή τάση, μειώνουν τη σπατάλη ενέργειας κατά περίπου 18 τοις εκατό σε σχέση με παλιές, τεντωμένες αλυσίδες που χρησιμοποιούνται σε μεταφορείς σιτηρών. Ένα ακόμη πλεονέκτημα είναι πως οι εύκαμπτοι αυτοί ιμάντες επιτρέπουν στους μηχανικούς να σχεδιάζουν μηχανήματα που ταιριάζουν σε στενούς χώρους. Οι παραδοσιακοί τροχαλίες και οδοντωτοί τροχοί καταλαμβάνουν πολύ περισσότερο χώρο και χρειάζονται πολύπλοκες διαμορφώσεις για να λειτουργούν σωστά σε περιορισμένα περιβάλλοντα.

Διωστήριος Ιμάντας έναντι Αλυσίδας και Οδοντωτών Τροχών: Απόδοση και Εφαρμογές

Ενώ οι αλυσίδες και οι τροχαλίες ξεχωρίζουν σε εφαρμογές υψηλής ακρίβειας, οι ελαστικές ιμάντες κυριαρχούν εκεί όπου η χαμηλή συντήρηση και η μείωση του θορύβου είναι προτεραιότητα:

| Χαρακτηριστικό | Διαστηματικές ζώνες | Αλυσίδες | Στροφική μετάδοση |

|---|---|---|---|

| Μέγιστη Δυνατότητα Ροπής | 2.500 Nm | 10.000 Nm | 15.000 Nm |

| Επίπεδα θορύβου | ☰65 dB | ☰78 dB | ☰85 dB |

| Ανάγκες σε λίπανση | Κανένα | Εβδομαδιαία | Συνεχή |

| Χρόνια Υπηρεσίας | 8.000–12.000 ώρες | 5.000–7.000 ώρες | 10.000–15.000 ώρες |

Συστήματα οδήγησης με ιμάντα 30% μεγαλύτερα διαστήματα συντήρησης σε γεωργικές μηχανές σύμφωνα με δοκιμές στο πεδίο από κορυφαίους κατασκευαστές, καθιστώντας τα ιδανικά για σκληρές συνθήκες με σκόνη και υγρασία.

Σχεδιασμός και Μηχανική Υλικών Ιμάντων Τριγώνου Βαρέως Τύπου

Πρώτες Ύλες που Χρησιμοποιούνται στην Κατασκευή Ιμάντων Τριγώνου

Οι περισσότεροι σύγχρονοι τριγωνικοί ιμάντες κίνησης βασίζονται σε είτε EPDM είτε νεοπρένη ως βασικό υλικό. Αυτά τα υλικά αποτελούν περισσότερο από τα δύο τρίτα όλων των βιομηχανικών ιμάντων που παράγονται σύμφωνα με τις προδιαγραφές ISO 4184. Γιατί είναι τόσο δημοφιλή; Λοιπόν, παραμένουν εύκαμπτοι ακόμη και όταν η θερμοκρασία πέσει κάτω από το σημείο πήξης ή ανέβει πάνω από τη θερμοκρασία δωματίου, αντέχοντας από -40 βαθμούς Κελσίου μέχρι περίπου τους 120 βαθμούς χωρίς να χάσουν το σχήμα τους. Επιπλέον, αντέχουν αρκετά καλά στην έκθεση σε όζον και διάφορες χημικές ουσίες που θα μπορούσαν να διασπάσουν τον κανονικό καουτσούκ. Για εφαρμογές όπου οι ιμάντες χρειάζονται επιπλέον αντοχή, οι κατασκευαστές συχνά χρησιμοποιούν στρώματα από συνθετικά πολυμερή, όπως ύφασμα πολυαμιδίου με ενισχυμένη αντοχή στη θερμοκρασία. Η στρατηγική αυτή ενίσχυση βοηθά στην προστασία από φθορές, κάτι που είναι ιδιαίτερα σημαντικό σε μηχανήματα που υφίστανται συχνά υψηλές εντατικές ροπές.

Γεωμετρία Διατομής και η Επίδρασή της στην Πρόσφυση και την Αντοχή

Η σχήματος V γωνία 40 μοιρών ενισχύει σημαντικά την εσωτερική δράση στα αυλάκια της τροχαλίας. Μιλάμε για περίπου 30 τοις εκατό καλύτερη πρόσφυση σε σχέση με τα κοινά επίπεδα ιμάντια, όταν πραγματικά τα συγκρίνεις. Η τριγωνική διατομή κατανέμει τις δυνάμεις τάσης στις πιο δυνατές πλευρές του ιμάντα, διατηρώντας παράλληλα την ευελιξία εκεί που χρειάζεται να κάμπτεται περισσότερο. Όταν χρησιμοποιούνται σε εξαρτήματα με βαθύτερη μορφή, αυτοί οι ιμάντες κρατούν πιο σφιχτά κατά τη διάρκεια εντατικών εργασιών. Οι αγρότες ανέφεραν μείωση των ποσοστών ολίσθησης κάτω από 2% ακόμη και όταν τα μηχανήματά τους χρησιμοποιούνται σκληρά σε δύσκολες συνθήκες στο χωράφι.

Στρώσεις Ενίσχυσης: Καλώδια Υαλοΐνου και Ελαστικές Ενώσεις

Οι ίνες υαλοβάμβακα που τρέχουν κατά μήκος παρέχουν εντυπωσιακή αντοχή σε εφελκυσμό άνω των 25 kN ανά μέτρο, γεγονός που σημαίνει ότι αντέχουν καλά ακόμη και όταν υπόκεινται σε επαναλαμβανόμενα βαριά φορτία, χωρίς να τεντώνονται εκτός σχήματος. Οι ίνες αυτές ενώνονται χρησιμοποιώντας ειδικές τεχνικές βουλκανισμού και εγκλωβίζονται μέσα σε στρώσεις από χλωροπρενικό ελαστικό, το οποίο στην πραγματικότητα απορροφά τις δονήσεις κατά τη λειτουργία. Το σύνολο κατασκευάζεται σε στρώσεις, ώστε οι εσωτερικές ίνες να παραμένουν προστατευμένες από τη φθορά στην επιφάνεια. Επιπλέον, υπάρχει μια επιπλέον στρώση από υλικά ανθεκτικά στις κρούσεις, η οποία εμποδίζει τη διέλευση λίθων και θρυμματιών, κάτι που είναι πολύ σημαντικό για εξοπλισμό που χρησιμοποιείται σε γεωργικές εργασίες, όπως συγκομιστικά μηχανήματα και αροτήρες, όπου τέτοιου είδους ζημιές θα αποτελούσαν συνεχή πρόβλημα.

Συμμόρφωση με τα Πρότυπα της Βιομηχανίας (ISO, RMA) στην Παραγωγή Ιμάντων Μετάδοσης

Οι κατασκευαστές τηρούν τις προδιαγραφές διαστάσεων ISO 4183 και τις προδιαγραφές υλικού RMA IP-3-3 για να εξασφαλίσουν την ανταποκρισιμότητα. Αυτές οι προδιαγραφές απαιτούν δοκιμές εφελκυσμού, κύκλους επιταχυνόμενης γήρανσης και επιβεβαίωση της ροπής ολίσθησης σε όλα τα παραγωγικά παρτίδα. Η συμμόρφωση αποτρέπει τις καταστροφικές βλάβες καθώς τυποποιεί τις μεταβολές πάχους εντός ±0,8 mm και εξασφαλίζει ομοιομορφία εφελκυσμού σε εφαρμογές μετάδοσης κίνησης.

Εφαρμογές Ιμάντα Κίνησης στη Γεωργική Μηχανική: Αξιοπιστία σε Δύσκολες Συνθήκες

Συνηθισμένα Γεωργικά Μηχανήματα που Χρησιμοποιούν Τριγωνικούς Ιμάντες Κίνησης για Μετάδοση Κίνησης

Οι περισσότεροι σύγχρονοι γεωργικοί μηχανισμοί βασίζονται σε τριγωνικούς ιμάντες για τη μεταφορά ισχύος, με περίπου το 85% των τρακτέρ, ελκυστήρων και δέσμης να χρησιμοποιεί αυτήν την τεχνολογία. Το χαρακτηριστικό τραπεζοειδές σχήμα αυτών των ιμάντων τους παρέχει σταθερή πρόσφυση στις τροχαλίες, κάτι που βοηθά στην αποδοτική μεταφορά ισχύος σε σημαντικά εξαρτήματα, όπως σπειροφόροι, αλωνιστήρες και οι μεγάλοι αντλητικοί σταθμοί άρδευσης που είναι τόσο απαραίτητοι για τους αγρότες. Αυτοί οι ιμάντες έχουν και μια άλλη πλευρά, δεν χρειάζονται λίπανση, σε αντίθεση με τις αλυσίδες που χρειάζονται συνεχώς λίπανση. Αυτό τους καθιστά ιδιαίτερα κατάλληλους για χρήση σε εξοπλισμό επεξεργασίας σιτηρών, αφού δεν υπάρχει κίνδυνος λάδι να μπει στο προϊόν, κάτι που μπορεί να είναι πραγματικό πρόβλημα κατά την περίοδο της συγκομιδής, ότανο κάθε κοκκάρι μετράει.

Περιστατικό: Μηχανήματα με Ιμάντα Τροχαλιών Τρακτέρ και Ελκυστήρων στις Φάρμες της Μέσης Ανατολής

Μια ανάλυση του 2023 για 120 φάρμες στη Μέση Ανατολή αποκάλυψε ότι οι σποροθέτες με ιμάντα λειτουργούσαν 18% περισσότερο μεταξύ βλαβών σε σχέση με τα μοντέλα με αλυσίδα. Οι χειριστές ανέφεραν 40% ταχύτερη αντικατάσταση ιμάντων σε σχέση με τις επισκευές κιβωτίου ταχυτήτων, ελαχιστοποιώντας τον χρόνο αδράνειας κατά τις κρίσιμες περιόδους συγκομιδής. Η μελέτη επισήμανε πώς οι σωστά τεντωμένοι ιμάντες διατηρούσαν σταθερές ταχύτητες θρυμματισμού παρά τις ξαφνικές αλλαγές φορτίου από άνισες πυκνότητες καλλιεργειών.

Προκλήσεις από σκόνη, υγρασία και μεταβλητά φορτία σε γεωργικά περιβάλλοντα

Οι ιμάντες κίνησης στη γεωργία αντιμετωπίζουν τρεις κύριες απειλές:

- Αποξεστική σκόνη : Μειώνει τη διάρκεια ζωής του ιμάντα κατά 30% σε ξηρές περιοχές (Έκδοση Μηχανικής Γεωργικών Μηχανημάτων 2024)

- Εισήγηση υγρασίας : Προκαλεί ολίσθηση τροχαλιών κατά τη διάρκεια των κύκλων της δροσιάς το πρωί

- Κρουστικά φορτία : Οι δέτες παραγωγής βολών παράγουν 3× την κανονική ροπή κατά τις φάσεις συμπίεσης

Σύγχρονα συμπολυμερή αιθυλενίου-προπυλενίου-διενίου αντέχουν πλέον στη διόγκωση σε υγρές συνθήκες και αποβάλλουν αποτελεσματικά τη συσσώρευση σωματιδίων.

Διαστήματα συντήρησης και καλύτερες πρακτικές αντικατάστασης στο πεδίο

Εφαρμόστε κύκλο επιθεώρησης κάθε 200 ώρες:

| Σημείο Ελέγχου | Εργαλείο | Ανοχή |

|---|---|---|

| Τάση | Μετρητής Απόκλισης | ½" ανά 12" άνοιγμα |

| Ευθυγράμμιση Τροχαλίας | Λέιζερ Ευθυγράμμισης | ±0,5° γωνιακότητα |

| Επιφανειακές Ρωγμές | Φακός μεγέθυνσης | Καμία ορατή ρωγμή |

Οι αντικαταστάσεις στο πεδίο διαρκούν λιγότερο από 45 λεπτά όταν χρησιμοποιούνται ιμάντες προ-τάνυσης και αυτοκλειόμενες κωνικές υποδοχές. Φυλάσσετε τους ανταλλακτικούς ιμάντες σε δοχεία προστασίας από το υπεριώδες φως για να αποφεύγεται η φθορά πριν την εγκατάσταση.

Απόδοση και Διάρκεια Ζωής Ιμάντων Μετάδοσης σε Βιομηχανικές και Γεωργικές Εφαρμογές

Αντοχή σε Εφελκυσμό και Αντίσταση σε Ολίσθηση σε Εφαρμογές Μειωτήρων Υψηλής Ροπής

Οι σημερινές ιμάντες μετάδοσης μπορούν να μεταφέρουν ενέργεια με απόδοση περίπου 95% σε βιομηχανικούς μειωτήρες χάρη στον συνδυασμό ισχυρών υλικών, όπως αραμίδιοι ίνες και ελαστικό ενισχυμένο με άνθρακα. Αυτά τα εξαρτήματα αντέχουν δυνάμεις πολύ πάνω από 15 kN ανά τετραγωνικό χιλιοστό, αλλά δεν τεντώνονται πολύ, κάτι που είναι πολύ σημαντικό για να αποφεύγεται η ολίσθηση όταν τα μηχανήματα φτάνουν στις μέγιστες συνθήκες φορτίου, όπως κατά την εκκίνηση εκείνων των μεγάλων ελικοφόρων σωλήνων στις φάρμες. Μερικές δοκιμές στο πεδίο έχουν δείξει πραγματικά ότι οι νεότερες V-ιμάντες με βελτιωμένες γωνιακές κορδέλες μειώνουν τα προβλήματα ολίσθησης κατά περίπου 40% σε σχέση με τις παλιές ελαστικές ιμάντες, όταν αντιμετωπίζουν την είδους ροπής που απαιτείται για τη διασπορά λιπασμάτων σε επιφάνειες με ροπή άνω των 200 Newton μέτρων.

Θερμική Υποβάθμιση και Διασπορά Θερμότητας Κατά τη Διάρκεια Συνεχούς Λειτουργίας

Όταν τα τρακτέρ λειτουργούν χωρίς διακοπή για εκείνες τις μακριές 16ώρες ημέρες συγκομιδής, η θερμοκρασία στην επιφάνεια των ιμάντων κίνησης μπορεί να φτάσει στους 212 βαθμούς Φαρέναιτ (δηλαδή 100 βαθμούς Κελσίου), γεγονός που αποτελεί τη στιγμή εκείνη που το κανονικό καουτσούκ αρχίζει να χάνει περίπου το 30% της εφελκυστικής του αντοχής. Γι' αυτόν τον λόγο, οι ιμάντες υψηλής απόδοσης περιλαμβάνουν ειδικές στρώσεις EPDM ανθεκτικές στη θερμοκρασία, οι οποίες τους επιτρέπουν να παραμένουν ανέπαφοι ακόμη και όταν οι θερμοκρασίες ανεβαίνουν μέχρι και τους 257 βαθμούς Φαρέναιτ (ή 125 βαθμούς Κελσίου). Οι αγρότες έχουν παρατηρήσει επίσης ότι οι ενσωματωμένες στους σύγχρονους τροχούς ιμάντα των τρακτέρ αυλακώσεις ψύξης με αέρα βοηθούν σημαντικά στην καλύτερη διασπορά της θερμοκρασίας. Αυτές οι βελτιώσεις στον σχεδιασμό μειώνουν τη θερμοκρασία λειτουργίας κατά περίπου 18 βαθμούς Φαρέναιτ (περίπου 10 βαθμούς Κελσίου), σύμφωνα με ορισμένες πρόσφατες δοκιμές που πραγματοποιήθηκαν το 2023 με χρηματοδότηση από το USDA.

Ανάλυση Διάρκειας Ζωής: Δεδομένα από Πραγματικές Δοκιμές στο Πεδίο

| Κατάσταση | Κανονική Διάρκεια Ζωής Ιμάντα | Διάρκεια Ζωής Ιμάντα Υψηλής Ποιότητας |

|---|---|---|

| Στεγνή συγκομιδή | 8–12 μήνες | 18–24 μήνες |

| Υγρή συγκομιδή | 4–6 μήνες | 10–14 μήνες |

| Πολύ σκόνη | 6–9 μήνες | 12–16 μήνες |

Η αγορά βιομηχανικών V ιμάντων δείχνει ότι το 72% των αντικατεστημένων ιμάντων εξακολουθούσαν να έχουν πάνω από 40% υπόλοιπη διάρκεια ζωής, γεγονός που επισημαίνει την ανάγκη για βελτίωση της εκπαίδευσης συντήρησης. Τα συστήματα προληπτικής συντήρησης που χρησιμοποιούν ανάλυση κραδασμών επεκτείνουν πλέον τα διαστήματα συντήρησης κατά 30% στις αυτοματοποιημένες βοσκοτόπιες.

Ορθή Εγκατάσταση και Ευθυγράμμιση για Μεγιστοποίηση της Απόδοσης των Ιμάντων Μετάδοσης

Ορθές Τεχνικές Έντασης για Μεγαλύτερη Διάρκεια Ζωής των Ιμάντων

Η σωστή τάση στις ιμάντες μετάδοσης είναι πολύ σημαντική για την καλή λειτουργία των συστημάτων μειωτήρα. Αν ένας ιμάντας είναι πολύ χαλαρός, θα ολισθαίνει και θα φθείρεται πιο γρήγορα. Αν όμως είναι πολύ σφιχτός, ασκεί επιπλέον πίεση στα ρουλεμάν, μειώνοντας την αποδοτικότητα της μετάδοσης κάπου μεταξύ 15% και 20%. Οι περισσότεροι επαγγελματίες της βιομηχανίας προτείνουν να ελέγχεται η καμπύλη του ιμάντα με ένα ποιοτικό όργανο μέτρησης της τάσης στο σημείο όπου ο ιμάντας καλύπτει τη μεγαλύτερη απόσταση. Η γενική πρακτική είναι περίπου μισή ίντσα βέλος (sag) ανά πόδι μήκους ιμάντα. Οι ομάδες συντήρησης θα πρέπει να ελέγχουν αυτήν την τάση τακτικά, ίσως μία φορά κάθε 500 ώρες λειτουργίας του συστήματος, αφού οι ιμάντες τείνουν να χαλαρώνουν με την πάροδο του χρόνου. Έρευνες δείχνουν ότι όταν οι τεχνικοί ρυθμίζουν σωστά την τάση, οι ιμάντες διαρκούν περίπου 2,5 χρόνια αντί για μόλις 18 μήνες όταν η ρύθμιση είναι λανθασμένη. Επιπλέον, η σωστή τάση μειώνει τις ενοχλητικές δονήσεις έως και 70%. Μην ξεχνάτε να ακολουθείτε πάντα τις συστάσεις του κατασκευαστή του εξοπλισμού και να χρησιμοποιείτε πάντοτε εργαλεία που είναι σωστά βαθμονομημένα για ακριβείς μετρήσεις.

Ευθυγράμμιση Τροχαλιών: Αποφυγή Πρόωρης Φθοράς και Απωλειών Ισχύος

Οι κακοστοιχειωμένες τροχαλίες προκαλούν ανομοιόμορφη φόρτιση της ιμάντας, με αποτέλεσμα την πρόωρη φθορά των άκρων και απώλειες ισχύος έως 18%. Η βέλτιστη ευθυγράμμιση απαιτεί:

- Γωνιακή ακρίβεια : Οι άξονες πρέπει να παραμένουν αυστηρά παράλληλοι

- Ακτινική ρύθμιση : Οι τροχαλίες να είναι ευθυγραμμισμένες στο ίδιο επίπεδο εντός ανοχής 0,5 mm

Τα συστήματα ευθυγράμμισης με λέιζερ παρέχουν την υψηλότερη ακρίβεια, αν και τα σταθερά χάρακες είναι αρκετά για βασικές διατάξεις. Στοιχεία από την πράξη δείχνουν ότι το 87% των βλαβών της ιμάντας οφείλεται σε κακή ευθυγράμμιση, που δημιουργεί περιττή θερμότητα και επιταχύνει τη φθορά των ελκυστικών καλωδίων. Επαναλήψτε την ευθυγράμμιση μετά από κραδασμούς ή ως μέρος της προληπτικής συντήρησης κάθε τρίμηνο.

Διαδικασία Αντικατάστασης Ιμάντα Μετάδοσης Βήμα-Βήμα

Ακολουθήστε αυτήν τη σειρά για αξιόπιστη εγκατάσταση V-ιμάντα σε μειωτήρια κιβώτια:

- Απενεργοποιήστε όλες τις πηγές ενέργειας χρησιμοποιώντας διαδικασίες που εγκρίνει ο κατασκευαστής

- Χαλαρώστε τα παξιμάδια στερέωσης του κινητήρα για να δημιουργηθεί χαλάρωση

- Αφαιρέστε τη φθαρμένη ζώνη χωρίς εργαλεία μοχλού για να αποφευχθεί η ζημιά στον τροχό

- Καθαρίστε τις αυλακώσεις με μη διαβρωτικές λύσεις, βεβαιώνοντας ότι δεν παραμένει κανένα ίχνος λιπαντικού

- Τοποθετήστε τη νέα ζώνη στη θέση της στις εγκοπές χωρίς στρέβλωση

- Εφαρμόστε τάση σύμφωνα με τις προδιαγραφές καμπύλης (ανοχή ±5%)

- Επιβεβαιώστε την παράλληλη ευθυγράμμιση των τροχών

- Περιστρέψτε χειροκίνητα πριν επαναφέρετε την παροχή ηλεκτρικής ενέργειας

- Καταγράψτε τις ημερομηνίες αντικατάστασης και τις τιμές τάσης

Η σωστή εκτέλεση μειώνει τα χρονικά διαστήματα αντικατάστασης κατά 40% και διατηρεί την απόδοση μετάδοσης ισχύος σε επίπεδο άνω του 98%, σύμφωνα με δεδομένα πεδίου

Συχνές Ερωτήσεις

Τι καθιστά τις ιμάντες μετάδοσης πιο αποτελεσματικές από τις αλυσίδες ή τους οδοντοτροχούς;

Οι ιμάντες κίνησης είναι πιο αποτελεσματικοί όσον αφορά τη μείωση του θορύβου, τη συντήρηση και τις απαιτήσεις χώρου. Ενώ οι αλυσίδες και οι οδοντωτοί τροχοί είναι καλύτεροι για εφαρμογές υψηλής ακρίβειας και υψηλής ροπής, οι ιμάντες κίνησης λειτουργούν καλύτερα εκεί όπου απαιτείται χαμηλή συντήρηση και πιο ήσυχη λειτουργία.

Πόσο συχνά πρέπει να ελέγχονται οι ιμάντες κίνησης στους μειωτήρες κινητήρων;

Οι ιμάντες κίνησης πρέπει γενικά να ελέγχονται κάθε 200 ώρες λειτουργίας. Οι τακτικοί έλεγχοι διασφαλίζουν ότι οι ιμάντες παραμένουν σωστά τεντωμένοι και ευθυγραμμισμένοι, μειώνοντας τη φθορά.

Ποιες είναι οι κύριες απειλές για τους ιμάντες κίνησης στον γεωργικό εξοπλισμό;

Οι κύριες απειλές περιλαμβάνουν την αποξηραμένη σκόνη, τη διείσδυση υγρασίας και τις επιβαρύνσεις από κρούση. Αυτοί οι παράγοντες μπορούν να μειώσουν σημαντικά τη διάρκεια ζωής και την αποτελεσματικότητα των ιμάντων κίνησης, εάν δεν διαχειριστούν κατάλληλα.

Γιατί η σωστή τάνυση είναι απαραίτητη για τη διάρκεια ζωής των ιμάντων κίνησης;

Η σωστή τάνυση εμποδίζει την ολίσθηση και την υπερβολική πίεση στα ρουλεμάν, διασφαλίζοντας ότι το σύστημα λειτουργεί αποτελεσματικά και ότι οι ιμάντες διαρκούν περίπου 30% περισσότερο.

Ποια υλικά χρησιμοποιούνται στις ιμάντες τριγωνικής διατομής βαρέως τύπου;

Οι ιμάντες τριγωνικής διατομής κατασκευάζονται κυρίως από EPDM ή νεοπρένη, ενισχυμένα με υλικά όπως καλώδια από γυαλόνημα και συνθετικά πολυμερή, ώστε να αντέχουν στις διακυμάνσεις θερμοκρασίας και στην έκθεση σε χημικά.

Πίνακας Περιεχομένων

- Πώς οι ζώνες μετάδοσης επιτρέπουν αποτελεσματική μετάδοση ισχύος στα συστήματα μειωτήρα κινητήρα

- Σχεδιασμός και Μηχανική Υλικών Ιμάντων Τριγώνου Βαρέως Τύπου

-

Εφαρμογές Ιμάντα Κίνησης στη Γεωργική Μηχανική: Αξιοπιστία σε Δύσκολες Συνθήκες

- Συνηθισμένα Γεωργικά Μηχανήματα που Χρησιμοποιούν Τριγωνικούς Ιμάντες Κίνησης για Μετάδοση Κίνησης

- Περιστατικό: Μηχανήματα με Ιμάντα Τροχαλιών Τρακτέρ και Ελκυστήρων στις Φάρμες της Μέσης Ανατολής

- Προκλήσεις από σκόνη, υγρασία και μεταβλητά φορτία σε γεωργικά περιβάλλοντα

- Διαστήματα συντήρησης και καλύτερες πρακτικές αντικατάστασης στο πεδίο

- Απόδοση και Διάρκεια Ζωής Ιμάντων Μετάδοσης σε Βιομηχανικές και Γεωργικές Εφαρμογές

- Ορθή Εγκατάσταση και Ευθυγράμμιση για Μεγιστοποίηση της Απόδοσης των Ιμάντων Μετάδοσης

-

Συχνές Ερωτήσεις

- Τι καθιστά τις ιμάντες μετάδοσης πιο αποτελεσματικές από τις αλυσίδες ή τους οδοντοτροχούς;

- Πόσο συχνά πρέπει να ελέγχονται οι ιμάντες κίνησης στους μειωτήρες κινητήρων;

- Ποιες είναι οι κύριες απειλές για τους ιμάντες κίνησης στον γεωργικό εξοπλισμό;

- Γιατί η σωστή τάνυση είναι απαραίτητη για τη διάρκεια ζωής των ιμάντων κίνησης;

- Ποια υλικά χρησιμοποιούνται στις ιμάντες τριγωνικής διατομής βαρέως τύπου;